Project overview

A platinum and palladium mine located in south central Montana expanded production and needed to increase the sulfuric acid injection to control the pH buffering of the system.

Approach

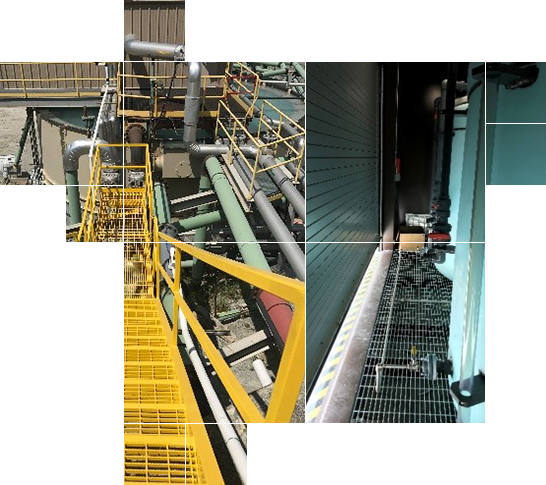

The client requested the installation of two new sulfuric acid injection points, which required the installation of 200 lineal feet of stainless-steel piping as well as supply tanks and chemical metering pumps. In addition to the piping, a structural access platform was fabricated and constructed on site.

By offering integrated services of structural fabrication and piping installation, Montana Ironworks was able to control the project schedule for procurement, fabrication and installation.

Coordination of this project included working with the mine operations and environmental teams to ensure there was little to no impacts on operations.

This work was performed while the facility maintained production with no effect on operations. Montana Ironworks procured and installed materials in a timely manner to meet the client’s schedule. This project was completed safely on time and on budget.